Because of the strong magnetic properties of NdFeB magnets, so compared to ferrite magnets, you can use small neodymium magnets can achieve a great ferrite performance, so more widely used in small generators, engines, electronic components, etc., so that the product can do a smaller size, Raiders larger, stronger performance.

The production of NdFeB magnets is compressed from a variety of materials powder, so NdFeB magnets is easy to easy to manufacture into a variety of shapes, such as: ring, arc, conical and other shapes, according to the customer's requirements for use. Moreover, the surface of NdFeB magnets can be plated, so that NdFeB magnets can be better applied to all kinds of humid, high temperature, low temperature, acid and alkali environments.

Our company sells NdFeB magnets in various sizes, shapes and performance grades, and can customize the n35 magnet according to the customer's usage environment.

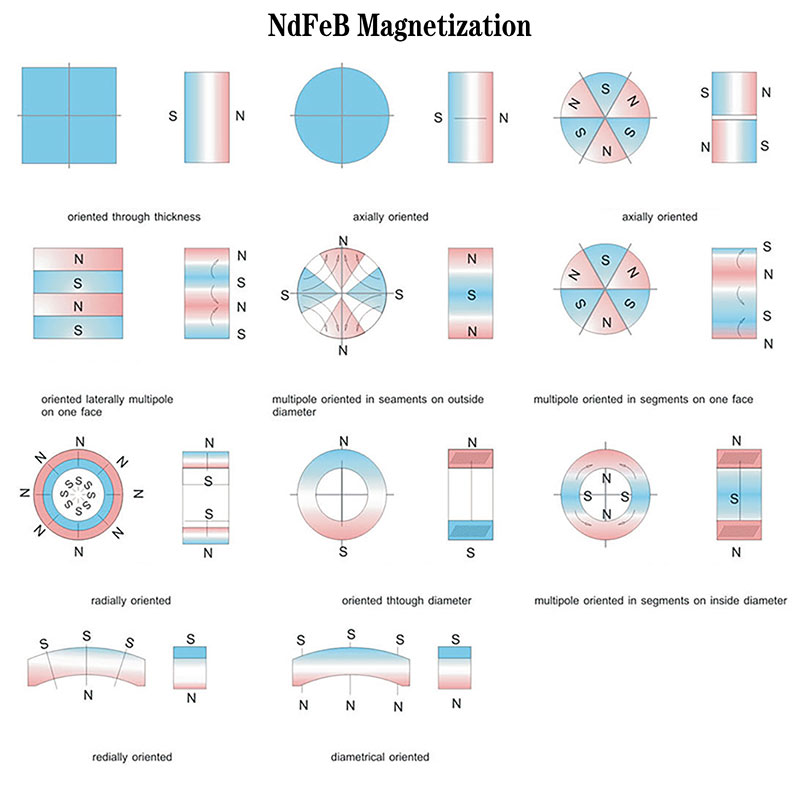

For the different environments and roles of n52 neodymium magnets, high powered magnets has different forms of magnetization to meet the requirements of product use.

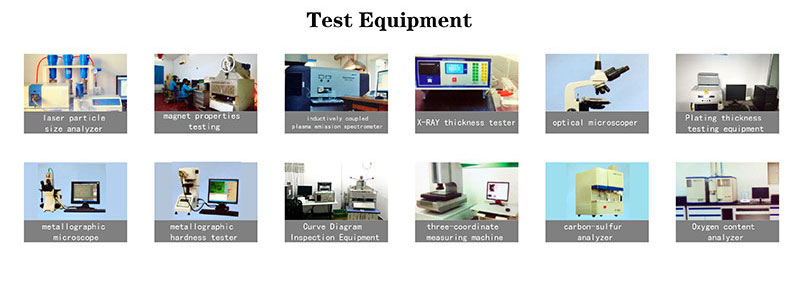

Our company has perfect magnet testing instruments, for each batch of high powered magnets shipped, we will carry out strict quality control, every data of the NdFeB magnets is tested and recorded, so that you can use it with peace of mind.

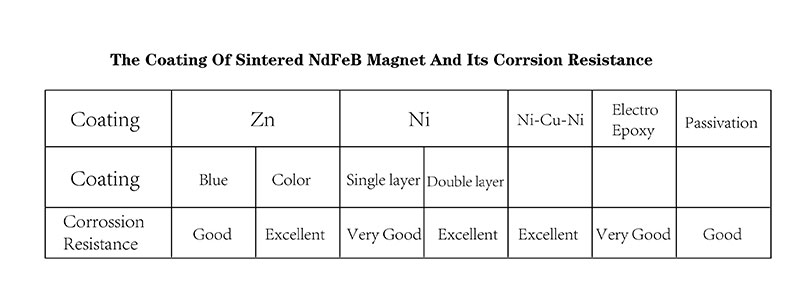

High powered magnets are used in different environments and have different requirements for surface plating. According to the customer's use environment, we can provide you with suitable surface treatment.

The Coating Of Sintered NdFeB Magnet And Corrosion Resistance

The material contains neodymium and iron ,so it is easy to rust when exposed to air .Therefore ,it is necessary to

treat the surface of neodymium ,iron and boron.

Pickling:In order to remove oxygen

Electroplating:Ni、Zn、Glod、Black Epoxy

Salt spray test(95%):48 hours ,coating quality