Ring strong neodymium magnets can be used where there is no ferrous material, can be used by external force fixed on the object, so that the object can use the magnetic field of the ring NdFeB to control some of the items that contain ferrous material.

Because NdFeB has the characteristics of high remanent magnetism, high coercivity and high energy, we can customize it according to the customer's actual use requirements.For the round hole in the middle of the magnet, we can customize all screw types, such as: M3, M4,M5,M6,M7,M8, etc.

Our company sells large neodymium magnets in various sizes, shapes and performance grades, and can customize the strong neodymium magnets according to the customer's usage environment.

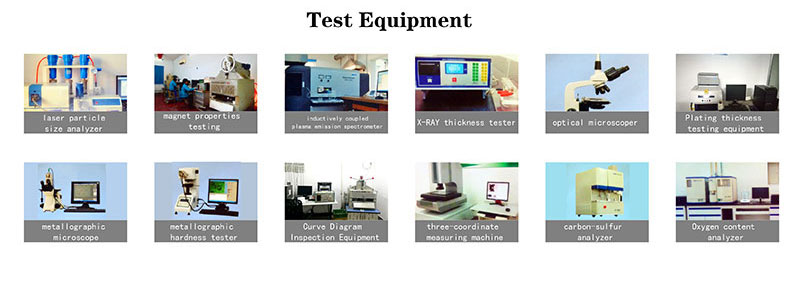

Our company has perfect magnet testing instruments, for each batch of strong neodymium magnets shipped, we will carry out strict quality control, every data of the magnet is tested and recorded, so that you can use it with peace of mind.

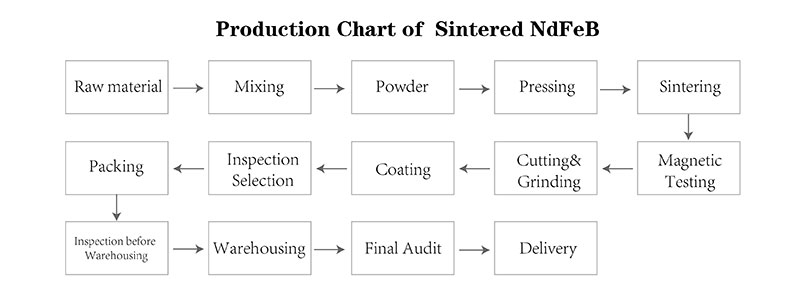

Strong neodymium magnets,the third generation of rare-earth permanent magnet ,is the most powerful and advanced and advanced permanent magnet today.NdFeB is named as “Magnet King” its high remanence , high coercive force , high energy .Moreover ,strong neodymium magnets has the high performance and high cost ration ,because of the rich rare earth resources in China and the ever-changing produciton process and technological progress.It can be easily foemed into various sizes and different shapes,such as segment 、ring、block andetc.The NdFeB production process is shown below.

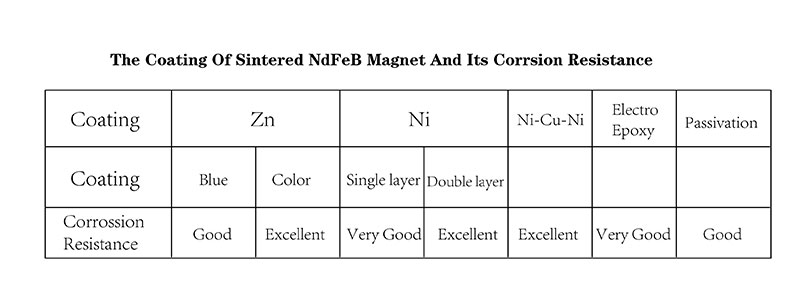

Strong neodymium magnets are used in different environments and have different requirements for surface plating. According to the customer's use environment, we can provide you with suitable surface treatment.

The Coating Of Sintered NdFeB Magnet And Corrosion Resistance

The material contains neodymium and iron ,so it is easy to rust when exposed to air .Therefore ,it is necessary to

treat the surface of neodymium ,iron and boron.

Pickling:In order to remove oxygen

Electroplating:Ni、Zn、Glod、Black Epoxy

Salt spray test(95%):48 hours ,coating quality