Material: neodymium iron boron magnet, iron base, rubber jacket

Rubber color: black

Magnetization direction: thickness magnetization

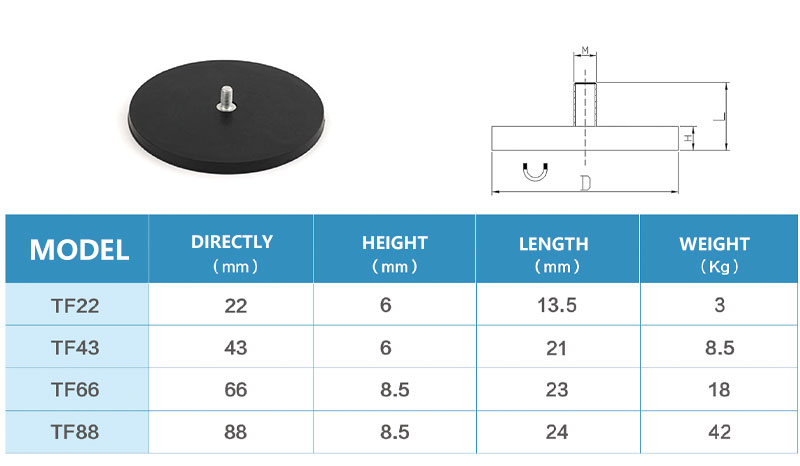

TT type rubber-coated magnet series are equipped with built-in threaded holes for use with screws.

Advantages of rubber coated magnets

1. Strong corrosion resistance rubber material itself is resistant to corrosion, usually the rubber coating will be much thicker than other types of neodymium magnets. This also makes this coating suitable for use in humid environments, thus playing a role in protecting the internal powerful magnets.2. High anti-slip rubber has high friction, ordinary coating in the smooth plane adsorption, easy to slip sideways, but the rubber coating will not.

3, good temperature characteristics of rubber coated magnets in high temperature 80 degrees Celsius, low temperature -40 degrees Celsius can work normally.

4, color variety of common black, but can also be adjusted to blue, yellow, green, and other colors as needed.

In summary, the rubber coating is suitable for use in harsh environments, but generally not conventional size, may need to open the mold, this situation is best to communicate with the magnet factory in advance.

NdFeB strong magnets are used in all kinds of industries, so the use of the environment is more complex. Our company can process the surface of the magnet according to the customer's requirements, such as: plating, inlaid in hardware fittings, wrapped in plastic, wrapped in silicone,,..,